Products

TPE for masturbator cup Ultrasoft TPE

Place of Origin China Product name TPE Raw Materials Color White Material TPE TPR TPV TPU TPO MOQ 1KG Keywords TPE Thermoplastic Elastomer Particles Sample Avaliable Packing Bag Delivery Time 3-5 Days Raw material Synthetic Rubber ...

Read More

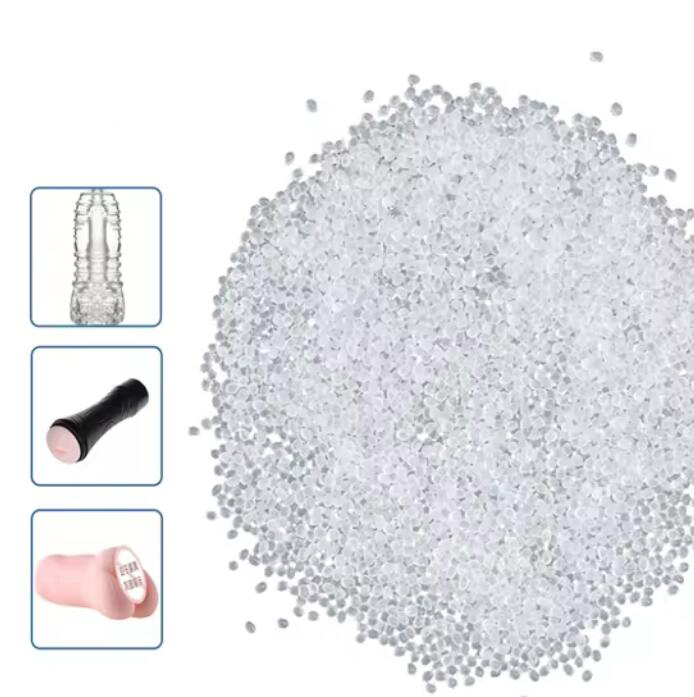

TPR handle rubber particles can be used as thermoplastic elastomers for sole materials

color black/white/customized Shape Plastic Granules Application electronic and electrical components, medical grade, shoe material Grade injection molding grade Feature transparent grade, Wear resistance Brand Name QS Place of Origin China Product name TPR Granules Appearance Plastic Granules Material Tpr Raw Material Resin Brand Name Qisheng Color Customizable Certificate COA MOQ 25kg Delivery Time 7-15days Sample Avaliable ...

Read More

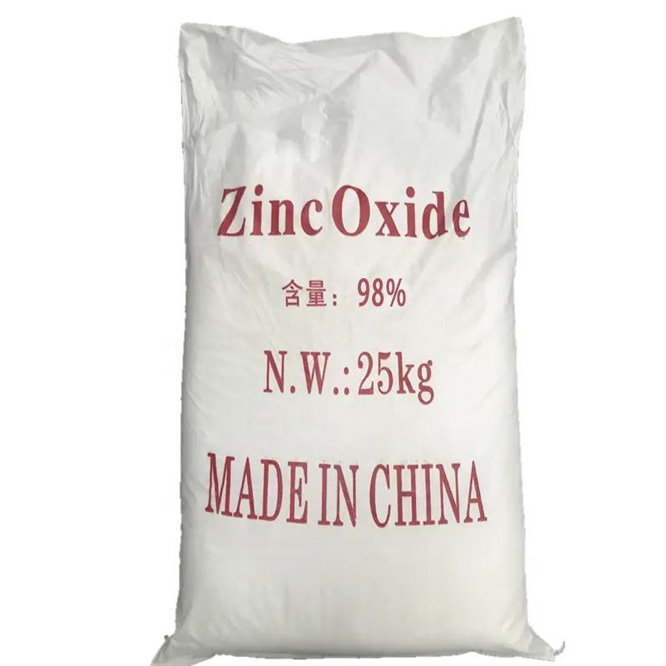

TPE TPR Raw Material Thermoplastic Elastomers TPE TPR

color white Application electronic and electrical components, General grade, wire and cable grades, special materials for cast films Materials, Food Grade Grade calendering, blown film grade, hollow grade, coating grade Feature High flow, aging resistance, reinforced grade, Powder Brand Name haosu Hardness 00A-120A Density 0.89-1.3g/cm3 Color Customizable MOQ 25kg Processing Method Injection Molding Certificate RoSH, REACH, FDA etc. Advantage Easy and Quick Demolding Product name TPE Raw Materials Sample Avaliable Delivery Time 3-5days ...

Read More

PET Resin CR

PET CR-8816 is for packing bottles, like pure water, natural mineral water, distilled water, drinking water PET CR-8863 is for small-package edible oil bottles, liquor bottles, medicine bottles, cosmetics bottles, PET sheets PET CR-8839 is for hot-filling bottles, like tea drinks, fruit-juice drinks and other medium type drinks PET CR-8828 is for carbonated drinks bottles and 3-gallon, 5-gallon big bottles PET CR-8828F is fast reheat chip for packing bottles of carbonated and soft drinks. Parameter Unit Grade PET CR-8816 PET CR-8863 PET CR-8839 PET CR8828 PET CR8828F I.V. dL/g 0.810 ± 0.020 ...

Read More

POM

Polyoxymethylene is a linear polymer with no side chains, high density, and high crystallinity. According to the chemical structure in the molecular chain, it can be divided into two types: homopolyformaldehyde and acetal copolymer. The important difference between the two is that the homopolyformaldehyde has high density, crystallinity and melting point, but the thermal stability is poor, the processing temperature range is narrow (about 10 ° C), the acid-base stability is slightly lower, and the copolymerized formaldehyde density, crystallinity, The melting point and strength are low, but the thermal stability is good, it is not easy to decompose, the processing temperature range is wide (about 50 ° C), and the acid-base stability is good. It is an engineering plastic with excellent comprehensive performance. Has good physical, mechanical and chemical properties, especially with excellent friction resistance. Commonly known as Saigang or Steel, it is the third largest general plastic. Suitable for making wear-resistant parts, transmission parts, and parts such as chemicals and instruments. 1) Excellent mechanical strength; 2)High hardness strength; 3)High wear resist ...

Read More

POM

Polyoxymethylene is a linear polymer with no side chains, high density, and high crystallinity. According to the chemical structure in the molecular chain, it can be divided into two types: homopolyformaldehyde and acetal copolymer. The important difference between the two is that the homopolyformaldehyde has high density, crystallinity and melting point, but the thermal stability is poor, the processing temperature range is narrow (about 10 ° C), the acid-base stability is slightly lower, and the copolymerized formaldehyde density, crystallinity, The melting point and strength are low, but the thermal stability is good, it is not easy to decompose, the processing temperature range is wide (about 50 ° C), and the acid-base stability is good. It is an engineering plastic with excellent comprehensive performance. Has good physical, mechanical and chemical properties, especially with excellent friction resistance. Commonly known as Saigang or Steel, it is the third largest general plastic. Suitable for making wear-resistant parts, transmission parts, and parts such as chemicals and instruments. 1) Excellent mechanical strength; 2)High hardness strength; 3)High w ...

Read More

POM

Polyoxymethylene is a linear polymer with no side chains, high density, and high crystallinity. According to the chemical structure in the molecular chain, it can be divided into two types: homopolyformaldehyde and acetal copolymer. The important difference between the two is that the homopolyformaldehyde has high density, crystallinity and melting point, but the thermal stability is poor, the processing temperature range is narrow (about 10 ° C), the acid-base stability is slightly lower, and the copolymerized formaldehyde density, crystallinity, The melting point and strength are low, but the thermal stability is good, it is not easy to decompose, the processing temperature range is wide (about 50 ° C), and the acid-base stability is good. It is an engineering plastic with excellent comprehensive performance. Has good physical, mechanical and chemical properties, especially with excellent friction resistance. Commonly known as Saigang or Steel, it is the third largest general plastic. Suitable for making wear-resistant parts, transmission parts, and parts such as chemicals and instruments. 1) Excellent mechanical strength; 2)High hardness strength; 3)High wear resist ...

Read More

PBT 605

PBT it is one of the advanced engineering plastics with high rigidity, high toughness, good fatigue resistance, weather resistance, low water absorption rate (all the properties maintain under moisture atmosphere including electrical properties), high dielectric ability, good electrical capacity, size stability, good formability, excellent anti-creep ability under high impact, and good chemical properties as well. It is easy to process into glass-fiber reinforced and flame-retardant products. PBT/PET can be ultrasonic welded and easily post-processed. ●High toughness, high modulus, low creep ●Good dielectric strength ●Good dimensional stability ●Low water absorption rate, good hydrolysis resistance ●Good heat resistance, low coefficient of thermal expansion ●High impact strength ●Resistance to Thermal aging ●Easy to process PBT 605 Flame-retardant Polybutylene Terephthalate Characteristics Meet the environmental standards of RoHS and IEC, high gloss, UL94 V-0 flame retardant,good light shading and ag ...

Read More

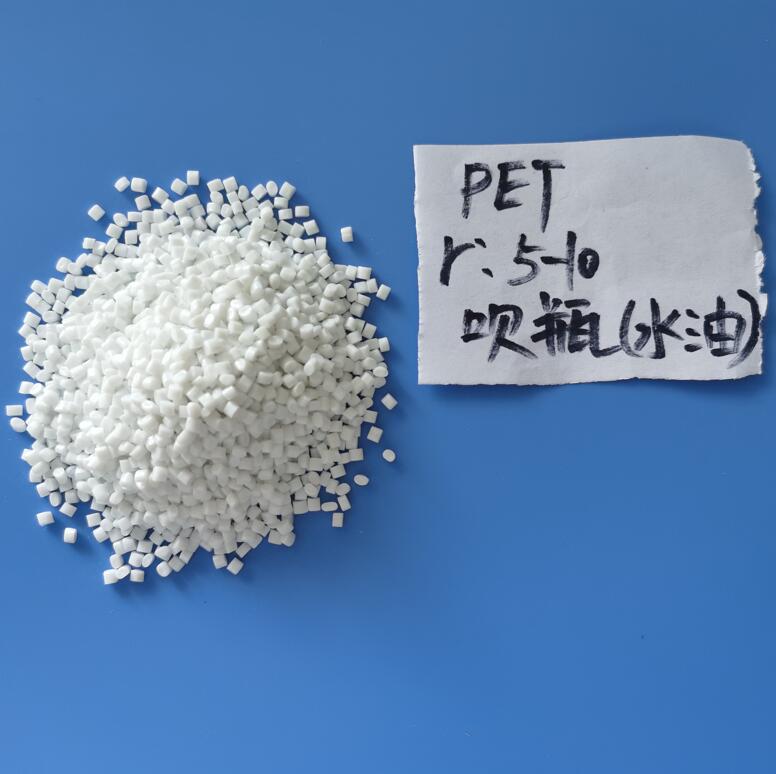

PET IV0.85

PET Resin is cream or pale-yellow crystal, with smooth and shiny surface. Resistance to creep deformation, fatigue resistance, abrasion resistance and dimensional stability are perfect. Small wear and tear but high hardness, its toughness is the largest in thermoplastic. The electrical insulation of PET is perfect and little be affected by temperature, however, poor corona resistance. PET is non-toxic, weather resistance, and anti-chemical stability is very good. PET is low water absorption, resistance to weak acids and organic solvents. Intolerance of hot water immersion and alkali. Item Unit Index I.V. dL/g 0.85±0.02 Crystallinity % ≤60 Color value L - ...

Read More

PET IV0.80

PET Resin is cream or pale-yellow crystal, with smooth and shiny surface. Resistance to creep deformation, fatigue resistance, abrasion resistance and dimensional stability are perfect. Small wear and tear but high hardness, its toughness is the largest in thermoplastic. The electrical insulation of PET is perfect and little be affected by temperature, however, poor corona resistance. PET is non-toxic, weather resistance, and anti-chemical stability is very good. PET is low water absorption, resistance to weak acids and organic solvents. Intolerance of hot water immersion and alkali. Item Unit Index I.V. dL/g 0.80±0.02 Crystallinity % ≤60 Color value L - ...

Read More

PET IV 0.78

PET chip is TPA-based polyethylene terephthalic copolymer designed for various applications, especially for the bottle like drinking water & food container. It is a high molecular weight polymer. It is low acetaldehyde content, good color, viscosity stability and low heavy metal content features, excellent further processing features like low processing temperature, high clarity and little degradation. I tem Unit Index I.V. dL/g 0.775±0.02 crystallinity % ≤60 Color value L -- ≥ 83 B Mpa ≤ -0.5 ...

Read More

EVA 28%

EVA It is a high flowability and high VA content ethylene vinyl acetate copolymer (EVA) with many excellent properties, such as characteristic flexibility and elasticity, thermal stability, good low temperature resistance, good compatibility and non-toxicity, etc. Product Features 1. Good softness and elasticity. 2. Good rebound performance, tension resistance and toughness. 3. Resistance to chemical attacks 4. Inclusiveness and cross-link ability. 5. Non-odor, non-toxic and anti-bacterial 6. Shockproof, soundproof and heat preservation EVA VA 28% Specification PROPERTIES TEST METHOD UNIT Data VA Content - % 28.0 Density ASTM D1505 g/cm3 ...

Read More

EVA 18%

EVA It is a high flowability and high VA content ethylene vinyl acetate copolymer (EVA) with many excellent properties, such as characteristic flexibility and elasticity, thermal stability, good low temperature resistance, good compatibility and non-toxicity, etc. EVA VA 18% Specification PROPERTIES TEST METHOD UNIT Data VA Content - % 18.0 Density ASTM D1505 g/cm3 0.937 Melt Index MI2.16 ASTM D1238 g/10min 1.5 Tensile Strength& ...

Read MoreCategories

Hot products

Agent